Mercedes-Benz Pioneers AI and Humanoid Robots in Berlin Factory Trial

Artificial intelligence (AI) and humanoid robots are at the forefront of an innovative manufacturing trial currently underway at the Mercedes-Benz Digital Factory Campus (MBDFC) in Berlin. U.S.-based Apptronik is partnering with Mercedes-Benz to explore the integration of AI, humanoid robots, and traditional production methods within the same facility.

Since 2022, the MBDFC has served as a hub for testing Mercedes-Benz’s future software applications in real-world production environments. The luxury vehicle manufacturer has integrated these advanced technologies into its globally utilized Mercedes-Benz Cars Operations 360 (MO360) digital production software ecosystem.

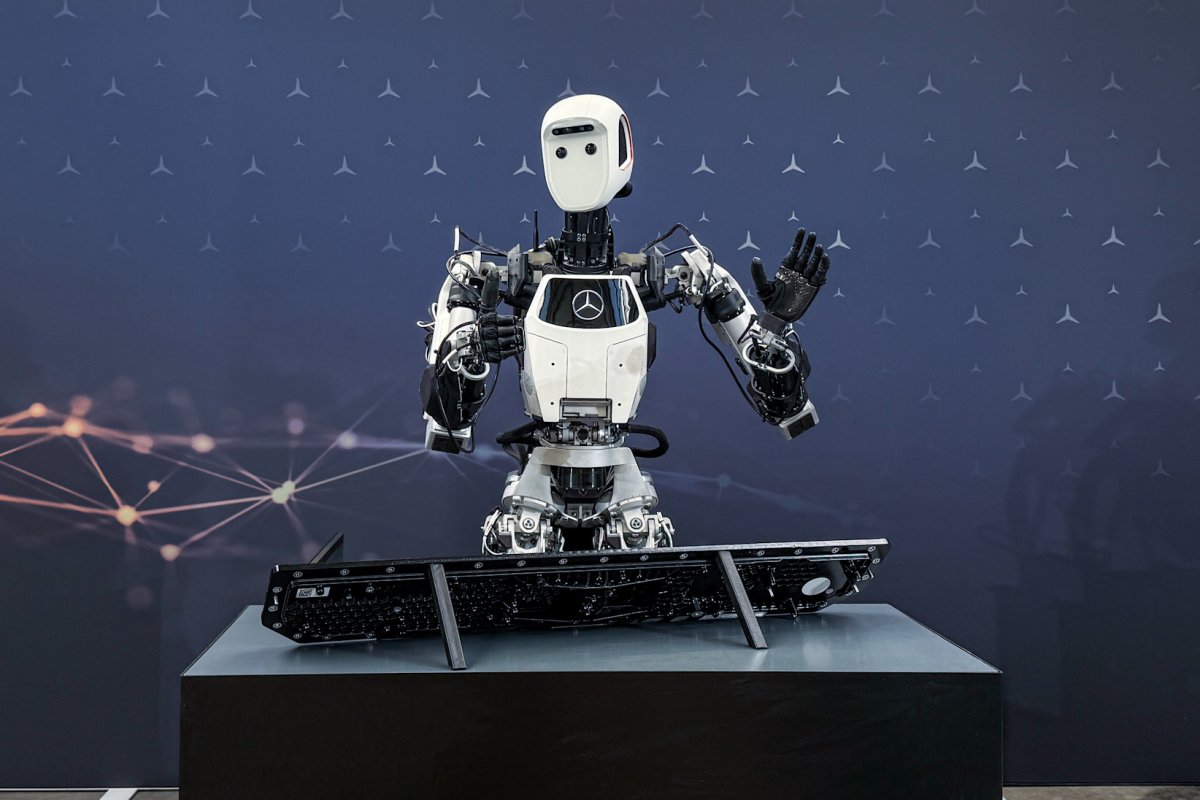

One of the key components of this trial is the Apptronik Apollo humanoid robot. Developed as a commercial robot, the Apollo is designed for safe, mass manufacturability and includes human-friendly interaction features. The robot is designed to perform a variety of tasks within the manufacturing setting.

Jeff Cardenas, Apptronik’s co-founder and CEO, spoke to Newsweek about the future of the technology. “We have these robots that you see all around us today,” Cardenas said. “They’re largely programmed to do one thing, but [what] the future looks like is to have one single robot that can do many different things, that can integrate seamlessly into these environments that are already built around humans, to work with us and change the way we live at work.”

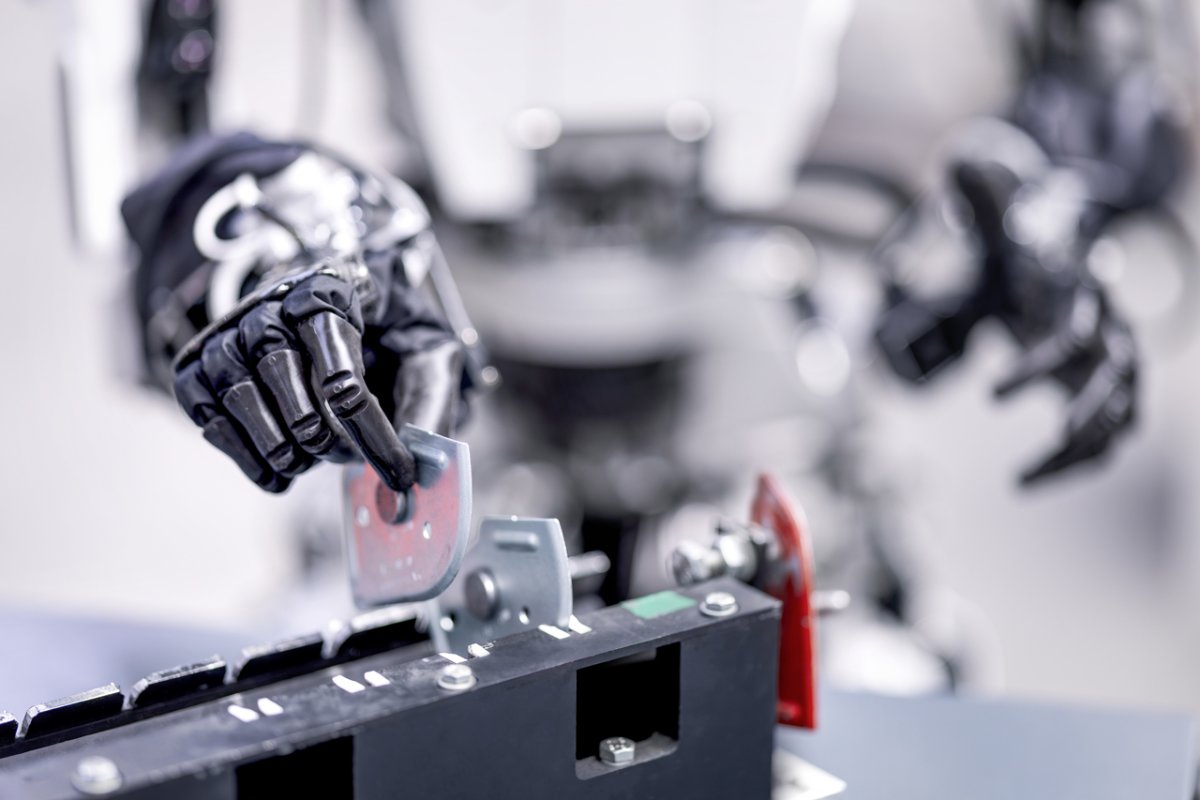

The initial phases of the trial focus on production tasks, with the robots handling repetitive duties within internal logistics, such as transporting components to the assembly line. Human workers then perform the assembly and carry out initial quality checks on the transported materials.

The robots are also gathering data and collaborating with Mercedes employees. This process involves transferring human knowledge to the robots using teleoperation and augmented reality technologies. Furthermore, this knowledge will be integrated into the MO360 system using AI-driven learning technology.

Cardenas described the initiative as a shift similar to the transition from mainframe computers to personal computers. “One of the ways that I explain this is you can think of this like personal computers in the early ’80s. These [robots] are basically mainframe computers, and what we’re entering is the personal computer era. I think the important thing for everyone to understand is the beginning of this journey,” he stated.

Mercedes-Benz is deploying AI within MO360 to make it “intuitive, accessible, and usable for everyone.” As part of this program, human employees can utilize the Mercedes Digital Factory Chatbot Ecosystem to ask questions and receive information from the company’s extensive production databases, eliminating the need to consult manuals or seek expert consultation.

Mercedes-Benz is also implementing AI to aid virtual assistants in real-time data analysis. This facilitates the quicker identification of quality deviations, which is expected to reduce recalls.

Jörg Burzer, a member of the Management Board for Production, Quality & Supply Chain at Mercedes-Benz Group AG, emphasized that these advancements are not meant to replace human workers. “It’s not a replacement of our team members working on the line. It’s at the end an addition,” he clarified.

Prior to this robotics trial, the MBDFC played a key role in preparing the company’s Rastatt plant for the production of the new Mercedes-Benz CLA, which was unveiled on March 13.

Burzer underscored the significance of MBDFC: “Mercedes-Benz Berlin-Marienfelde remains at the cutting edge of automotive production and keeps Germany on the map as a global center for innovation.”

Investment in German-based manufacturing and innovation has been a significant topic in the country’s discourse. As companies like Volkswagen Group have reduced employment numbers, BMW and Mercedes-Benz have also made moves to streamline their workforce.

A recent Horváth 2024 survey of automotive industry managers indicates that almost 60 percent of German automakers plan to reduce jobs in Germany by 2030. About 14 percent of the respondents stated that the job cuts would be “significant.”

Furthermore, the rise in regional manufacturing has gained traction, especially due to shifting global market powertrain demands, supply chain disruptions, and increasing shipping costs.

Frank Goller, a partner at Horváth, indicated to the German Press Agency in June that, despite job cuts, the German automakers are significantly investing in their future, noting “There is a high level of investment in the automation of production facilities and digitalization.”

Burzer revealed that the current investment in the humanoid robot project is “likely less” than what Mercedes initially invested in robotics during the early 1970s.

He concluded that “Artificial intelligence and humanoid robots open up an exciting new frontier which make automotive production more sustainable, efficient and more intelligent.”

Mercedes-Benz views efficiency as crucial, particularly considering significant investments in software and hardware R&D. Concurrently, they’re balancing the decreased demand for battery-electric vehicles than initially projected. Moreover, they’re preparing for predicted global economic challenges, including the decline in foreign auto sales in China.

Mercedes-Benz is investing millions in Apptronik, solidifying this robotics partnership. Burzer anticipates widespread implementation of humanoid robots across Mercedes factories by 2030. The estimated cost per robot is between $9,000 and under $100,000.

The company is focusing on implementation in the U.S. and Europe, with special attention to Germany due to its aging workforce. However, Burzer is quick to point out that a fully robotic workforce is not immediately on the horizon due to the complexities of car production.