Miami, March 4, 2025 – The rise of electric vehicles (EVs) continues, with more on the road than ever before. However, a recent global survey revealed a significant percentage of EV owners, nearly half in the U.S., have considered switching back to gasoline cars. The primary reason cited: charging concerns.

While the range of electric vehicles has progressively increased, consumers’ expectations still outpace the capabilities of current lithium-ion batteries. Now, researchers at Florida International University (FIU) have achieved a significant advance in battery technology, known as ‘beyond lithium-ion,’ that could revolutionize the convenience of EV ownership.

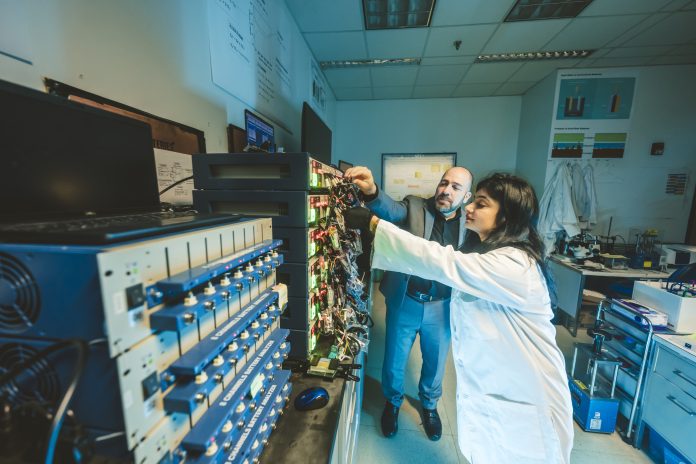

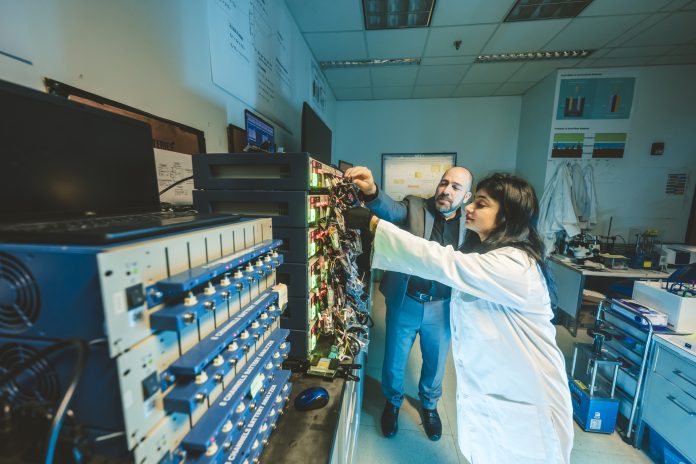

“We began working with these next-generation battery chemistries eight years ago. The initial charging cycle was excellent, but by cycle 20, the battery was essentially useless,” explained Bilal El-Zahab, an associate professor in the College of Engineering & Computing. “We had to become battery whisperers to overcome these challenges, so it’s truly exciting to reach this stage.”

El-Zahab and his team at the FIU Battery Research Lab focused on lithium-sulfur, a promising beyond lithium-ion technology and a leading alternative to lithium-ion. This technology is both lightweight and less expensive, with impressive energy density, leading to improved charge capacity. This translates to increased range for electric vehicles, and longer operating times for laptops, smartphones and other devices – potentially doubling their lifespan.

However, lithium-sulfur’s chemical properties, whilst enabling extended battery life, also limited the longevity of the battery itself, rendering it ineffective after approximately 50 complete charge cycles.

After years of rigorous testing, El-Zahab’s team discovered a solution to increase the lifespan of lithium-sulfur batteries. The answer proved to be a simple addition of a small amount of metal. Platinum stabilizes the battery’s performance, boosting its storage capacity, bringing this technology closer to commercial viability. The results of their research were recently published in Energy and Environmental Materials.

“We achieved a 92% retention rate after 500 charging cycles, meaning the battery is almost as good as new,” stated Aqsa Nazir, an FIU postdoctoral researcher in El-Zahab’s lab and the study’s first author. “This also demonstrates that we minimized the negative reactions that hinder overall performance, bringing this battery to the commercial level.”

All batteries operate on a straightforward principle: During charging, ions move from one side of the battery to the other, and back again when releasing energy. However, with lithium-sulfur, the process is more complex. The sulfur side of the battery is made of lithium, creating the other side. When lithium ions carrying a charge reach the sulfur side, a chemical reaction occurs between the lithium and sulfur, producing lithium-containing sulfur compounds called polysulfides, which are then transported to the lithium side during charging. This process causes a moss-like build-up on the lithium side, reducing energy efficiency and ultimately leading to the battery’s degradation.

To counteract this damaging chemical reaction, researchers added tiny nanoparticles of platinum to the sulfur side of the battery. In essence, similar to how a traffic officer directs flow to prevent accidents and backups, the platinum works on a molecular level to guide the lithium, ensuring its smooth flow. Only a minuscule amount – about 0.02% of the total battery – was sufficient to make a significant difference.

“Adding nanoparticles of platinum to the battery is akin to adding a pinch of salt to food: A small amount has a large impact,” El-Zahab stated.

El-Zahab’s lithium-sulfur battery is currently undergoing third-party testing, a vital step before the technology can be licensed and commercialized.